MASDFAB Celosia Column Research

Computational Design for Bespoke Robotic 3D Printing on Curved Support

Project Details

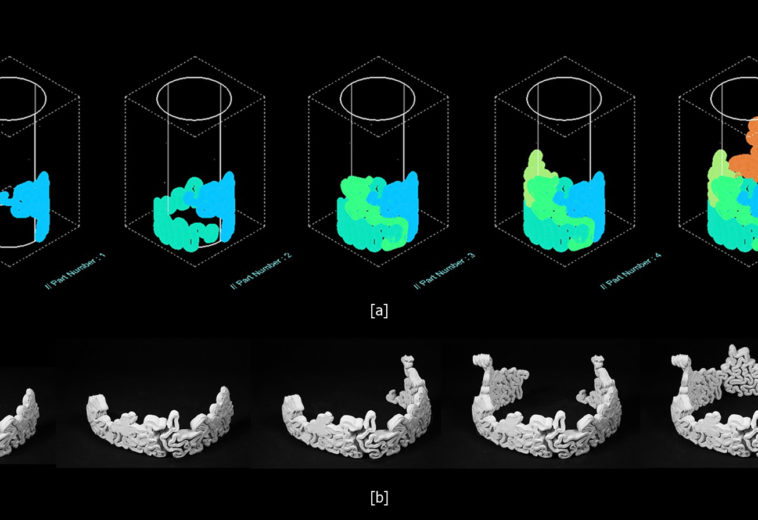

Additive manufacturing enables the fabrication of affordable customisation of construction elements. This paper presents a computational design method developed for 3D printing of unique interlocking ceramic components, which assemble into segmented columns. The fabrication method is ceramic-paste extrusion, robotically placed on semi cylindrical molds. Material system and fabrication setup contribute to the development of an integrated generative system which includes overall design, assembly logic and printing tool-path. MASDEFAB ETH ZurichMASDFAB Celosia Column

Ceramic Components

Additive manufacturing enables the fabrication of affordable customization of construction elements. This Project presents a computational design method developed for 3D printing of unique interlocking ceramic components, which assemble into segmented columns. The fabrication method is ceramic-paste extrusion, robotically placed on semi-cylindrical molds. Material system and fabrication setup contribute to the development of an integrated generative system which includes overall design, assembly logic and printing tool-path. By contextualizing clay extrusion and identifying challenges in bespoke tool-path generation, this paper discusses detailing opportunities in digital fabrication. Finally, it identifies future directions of research in extrusion-based printing.

Keywords: CAAD education, generative design, robotic 3D printing, clay extrusion, curved support

Additive manufacturing (AM) for architecture promises to enable affordable fabrication of building components with: customized features, geometric freedom, speed in fabrication and economy of materials. There are a multitude of techniques in which materials can be added to create a 3D object, from which, binder jetting, material extrusion, powder bed fusion, are the most used for large-scale objects. Each comes with specific fabrication attributes, opportunities and constraints. Relevant for this paper is extrusion-based AM, where material is expelled, as a filament, through a small size aperture, or nozzle, and overlaid in sections to approximate a desired form.

MATERIAL SYSTEM Clay exhibits rheological characteristics suitable for extrusion. When inside a pressurized container, the compressed clay mix remains homogeneous and can be guided out through a nozzle. As such, material is deposited on the print-path in layers directly proportional in size to the nozzle diameter. In combination with water, material flow behavior can be adjusted, from very dense paste to a liquid, and used inside multiple extruder systems. After drying and baking at temperatures above 550°C, the clay paste becomes insolvent in water and gains more compressive strength.

To avoid cracking and breaking, freshly printed parts need to slide along the formwork while drying. Therefore, using a support surface with a single curvature was necessary. Shrinkage was of particular importance to the research because the clay elements were printed on curved support. To avoid deviation from the cylindrical core, all parts were dried while still on the mold, therefore the curvature of components matches the designed tolerances. Finally, the clay components were baked at 960°C under the baking program illustrated in Figure 4. Except small deformations, no major failures, like breaking or cracking, were identified during visual inspection.

While some designs embrace the inaccuracies of clay fabrication, or feature the layer as prevalent aesthetic trait, it is obvious to us that AM with extruded materials may benefit from variation of layer trajectory both in terms of structural capacity, fabricability and aesthetics. In this context, the geometry of the layer extends design space and unlocks new opportunities for detailing in digital fabrication. Such a design approach can be extended to other extruded materials for architectural applications, like plastic, resin, foam or concrete. We present a generative design system for 3D printing ceramic elements that assemble into larger structures, in this case a segmented column. This system incorporates overall shape creation made of unique components that are printed using a project specific material deposition technique. Such an approach extends the overlap between design and fabrication for a faster production of large-scale 3d printed elements. Profiting from the fact that design, computation, material and fabrication experiments, happen synchronously, the presented design stream features a high degree of flexibility, offering an operable alternative to rigid process-automation for additive manufacturing of unique building components. The drawback of having bespoke material placement is given mainly by the complexity of the computational problem. Every geometry requires a unique computational solution. Recent developments in computational design for robotic fabrication encourage research into bespoke material placement

- Date : 18.09.2017

- Client : ETH Zurich

- Skills : Rhino 3D, Grasshopper, Python, ABB Robotic arm

- Location :